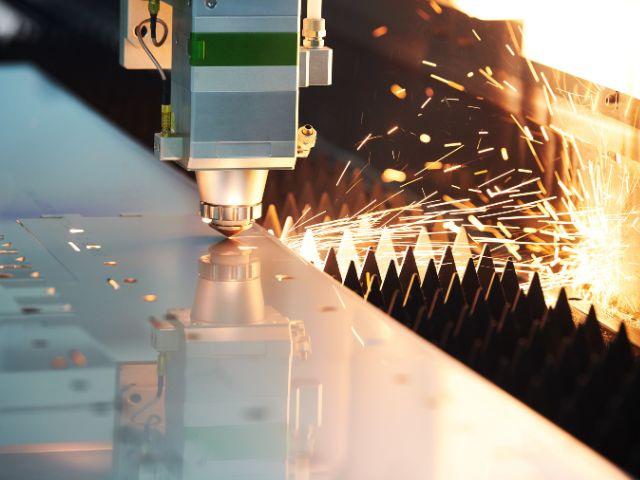

The realm of laser cutting has evolved drastically over the years, becoming a mainstay in various industries thanks to its precision, versatility, and efficiency. This technology is not only reshaping traditional manufacturing processes, but it’s also opening new avenues for innovation across multiple sectors. Here are some of the primary industries that should work with laser cutting.

The automotive industry has a long history of embracing innovative technologies to enhance production processes, and laser cutting is no exception. The ability to cut intricate shapes with exceptional precision makes laser cutting an invaluable tool for creating components ranging from engine parts to vehicle panels. This technology also enables the efficient cutting of high-strength materials, which are often used in modern vehicles for safety and weight reduction purposes.

In the world of electronics, where miniaturization and precision are key, laser cutting proves its worth. It’s used extensively in the production of printed circuit boards (PCBs), allowing for the accurate cutting of highly detailed designs without risking damage to the delicate components. Furthermore, laser cutting’s non-contact nature means less wear and tear on tools, making it a cost-effective solution for electronics manufacturers.

The medical industry relies heavily on accuracy, something laser cutting can provide in spades. It’s regularly used in the production of medical devices, from stents to surgical instruments. The technology’s ability to work with a broad range of materials—including metals and plastics—coupled with its precision makes it ideal for creating complex, miniature components often required in medical devices.

In the aerospace industry, where precision and material integrity are paramount, laser cutting is often the go-to technology. It’s used to cut various components, from turbine parts to airframes, ensuring a high degree of accuracy while maintaining the structural integrity of materials. The technology also allows for the cutting of complex shapes and patterns—something that’s often needed in aerospace component design.

Now that you know which industries should work with laser cutting, make sure you know the important factors to consider when hiring a laser cutting company—this information can help you find the best business to partner with.

24World Media does not take any responsibility of the information you see on this page. The content this page contains is from independent third-party content provider. If you have any concerns regarding the content, please free to write us here: contact@24worldmedia.com